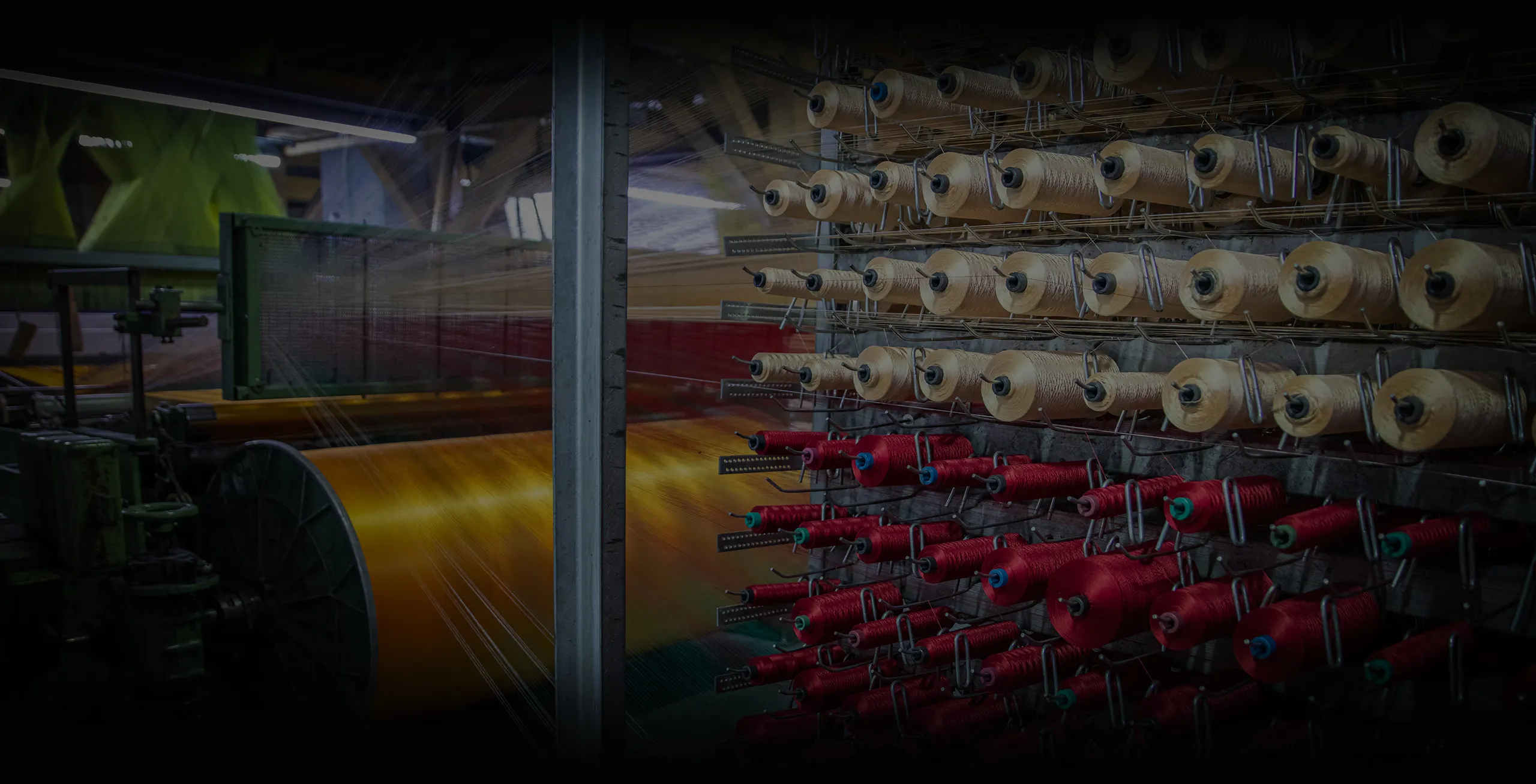

Incoming raw fibers such as cotton, wool, or synthetic materials are often weighed to assess their quality and ensure they meet the standards required to produce uniform batches of yarn and fabric. In addition, the weight of the fabric (grams per square meter or ounces per square yard) is a standard measure of fabric quality and consistency. When exploring new technological advancements R&D team will often need to assess the weight of the finished items, to assess their suitability for use.

Scales and weighing systems for textile manufacturing.

The National Council of Textile Organizations (NCTO) estimates that the U.S. industry is the second largest exporter of textile-related products in the world. The industry is comprised of a range of sub-industries, including yarn and fabric manufacturers, suppliers of cotton, wool, and man-made fibers, dyers, printers, and finishers, recycling facilities designed to convert textile and other waste to new textile uses and resins, and textile chemical industries.

The industry is about more than clothing – textile products are now major components in everything from heart valves and stents to aircraft bodies and advanced body armor.

With the U.S. Textile Complex creating next-generation textile materials like conductive fabric with anti-static properties, electronic textiles that can monitor heart rate and other vital signs, antimicrobial fibres, life-saving body armor and new fabrics that adapt to the climate to make the wearer warmer or cooler, the United States leads the world in textile research and development.

Weighing scales and systems are integral to various stages of textile manufacturing, ensuring quality, consistency, and efficiency.

Weighing finishing agents (such as softeners, flame retardants, and water repellents) is critical for achieving the desired finish without over or under-using expensive chemicals. When dyeing yarn, dye quantities are often calculated based on the weight of the yarn to ensure even and consistent color. When paired with sophisticated indicator or software, scales can also help to manage process control – for example adding dyes or chemicals to batches of yarn.

In any manufacturing operation, inventory management is key to minimizing downtime and ensuring a consistent production flow. Weighing scales and systems can be used to manage inventory and ensure that sufficient quantities of raw materials are available. Weighing scales can also link to back-office systems, allowing operators to collect data that can be used for quality control and traceability. Floor and forklift scales can be used to weigh bundled loads, while tanks and hoppers can be added to storage tanks and silos to weigh chemicals.

Accurate weighing helps in calculating the cost of raw materials and finished products, which can be essential for pricing strategies, and for covering the cost of outbound shipping. Monitoring the weight of waste materials also helps in identifying and minimizing waste, contributing to cost savings.

Solutions for Manufacturing

Find a weighing equipment supplier near me

We work with a network of reliable and trusted distribution partners to ensure that we can offer a truly personal, local service, wherever you’re located.