Overview

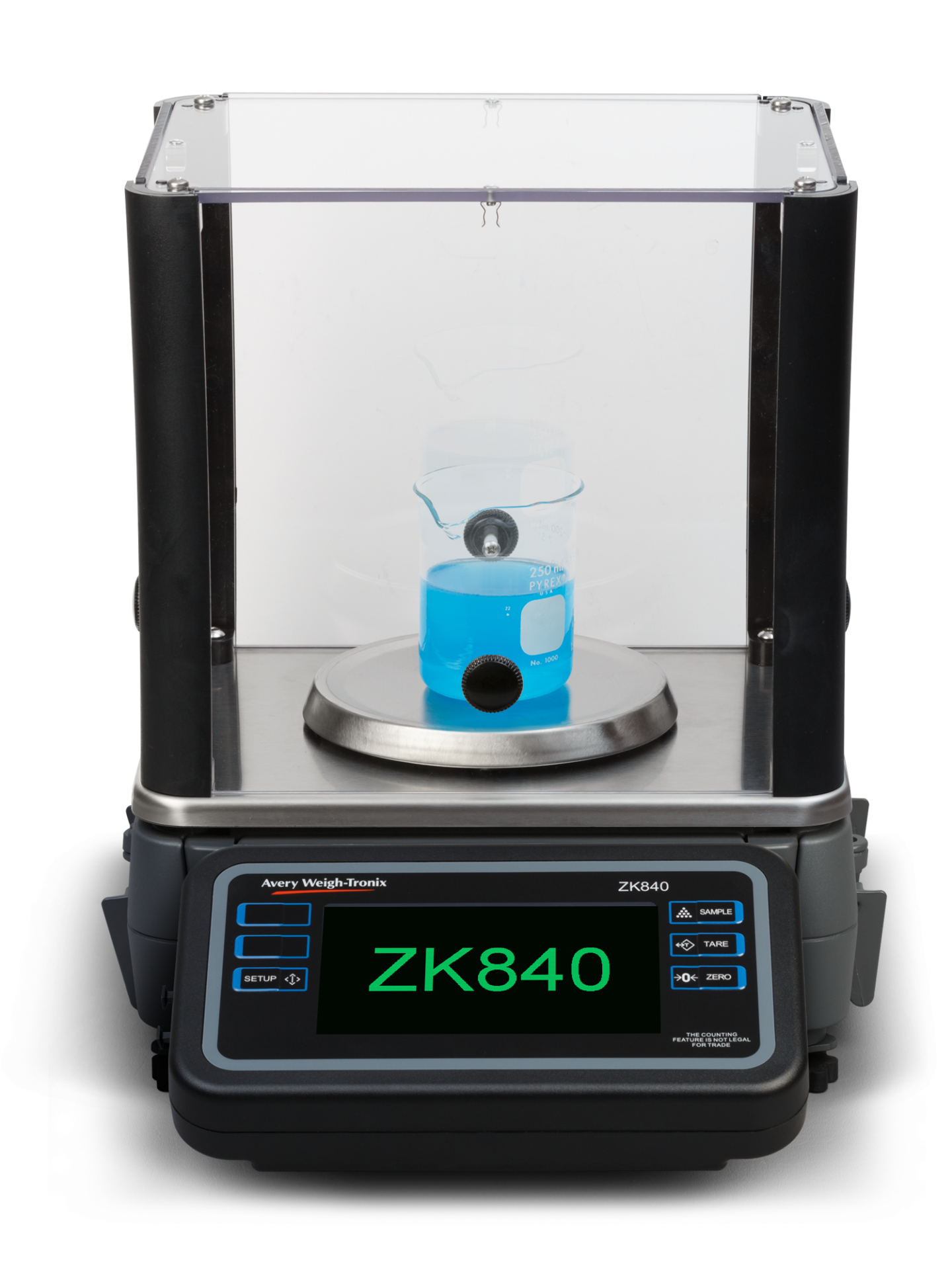

theThe ZK840 counting scale offers exceptional accuracy and flexibility. A fully programmable counting scale, with database inventory control and a suite of built-in applications, this high resolution touch-screen scale comes with flexibility, ease of use and precision in mind.

Exceptional Flexibility

At its simplest, the ZK840 can be used as a general high resolution weighing and counting scale. A host of applications, including checkweighing, with inventory control, balance and density weighing, recipe filling, grading and pick list programs are available for use and can also be fully customized if required.

Counting Scale with Inventory Control: Created to adapt to most inventory control processes, the ZK840 counts and samples components quickly and accurately, speeding up processes and improving efficiencies when counting large numbers of identical parts.

Built-in database inventory control packages store around to 5000 piece weights and provide business critical real-time stock data and statistical analysis that will help improve product line efficiency. The option to link to PLU Lookup, our external database system, enables users to capture, control and manage data for hundreds of thousands of parts on 32 linked scales. Find out more about the counting scale application.

Checkweighing and QA Management Application: With clear under, over and accept weight bands providing a simple visual indication of whether the package falls within tolerance, the ZK840 is ideal for fast and efficient checkweighing or end-of-line quality control. Find out more about the Checkweighing application

Balance and Density Weighing Application: With over 1 billion internal counts and a readability of over 3.5 million divisions the ZK840 offers precise lab-balance accuracy, density formulation, percentage weighing and percentage recipe on an industrial scale. The scale also conforms to the Good Laboratory Practices (GLP) quality system management. Find out more about the Balance application.

Grading Application: The ZK840 grading application and graphical display give users a clear indication of the grade and location of each item when segregating by weight. Comprehensive data such as running total per location, last weight/weight band and Parts-per-minute (PPM). This then provides a complete overview of the production process. Find out more about the Grading application.

Pick List Kitting Application: Combines filling, counting, checkweighing and QA applications to give an operator step by step picking instructions as on-screen prompts. On screen validation prevents missed steps. This reduces common picking errors. It also ensures that the correct parts and quantities have been picked. Find out more about the Pick List Kitting application.

Fully configurable solution: The ZK840 also offers a fully-configurable solution. The sleek design and user-friendly features provide an ideal platform to build a solution. They specifically program and tailor to your business. There’s no need to compromise.

Touch screen graphical weight display

The 5.3” x 2.75” (135mm x 75mm) touch screen graphical weight display offers ease of use and extreme durability. Graphics and text result in a more intuitive interface, allowing users to navigate applications using the touch screen.

Unrivaled Strength and Precision

An ideal counting scale for weighing micro-components or large items, the ZK840 features highly accurate Quartzell™ weighing technology. With 100,000 divisions (non legal for trade) or 10,000 divisions (legal for trade: OIML, NTEP and Measurement Canada). And also, a 1 billion internal count resolution, the scale offers unrivaled precision.

A robust die-cast enclosure provides 1100% overload protection. It also protects the cell from shock and dropped loads. This ensures accuracy and repeatability in even the most extreme conditions.

Product Resources

These resources help you get the most out of your Avery Weigh-Tronix product. Can't find what you're looking for? Contact Us

United States

United States  United Kingdom

United Kingdom  Canada

Canada  Canada (fr)

Canada (fr)  India

India  Ireland

Ireland